UNIVEST® INSULATION JACKETS UniVest® Insulation Jackets are “cost-effective” thermal insulation systems that help improve facilities in variety of ways

by minimizing costs and establishing greater operational stability. UniVest® Insulation Jackets are removable and reusable

for easy installation, easy removal and easy re-installation, making access to equipment and applications simple. These

collective advantages allow you to save on energy costs while reducing your organization’s overall carbon footprint.

| ITEM |

High Temperature Insulation Wrap |

FASTENING SYSTEM |

Strap/Buckle System |

| LENGTH |

31in / 787mm |

APPROX "R" FACTOR |

. 48 |

| WIDTH |

4in / 102mm |

MAX TEMP /

CONTINUOUS USE |

2000F / 1093C

900F / 483C |

| THICKNESS |

1in / 25mm |

COLOR |

Green |

| INSULATION MATERIAL |

Ceramic Fiberglass |

WEIGHT |

1.27lbs / 0.58kg |

| JACKET MATERIAL |

Teflon Coated Fiberglass Cloth |

FIT |

Universal |

| DIAMETER RANGE |

6in-8in / 152mm-203mm |

CIRCUMFERENCE RANGE |

19in-25in / 483mm-635mm |

FEATURES & BENEFITS:

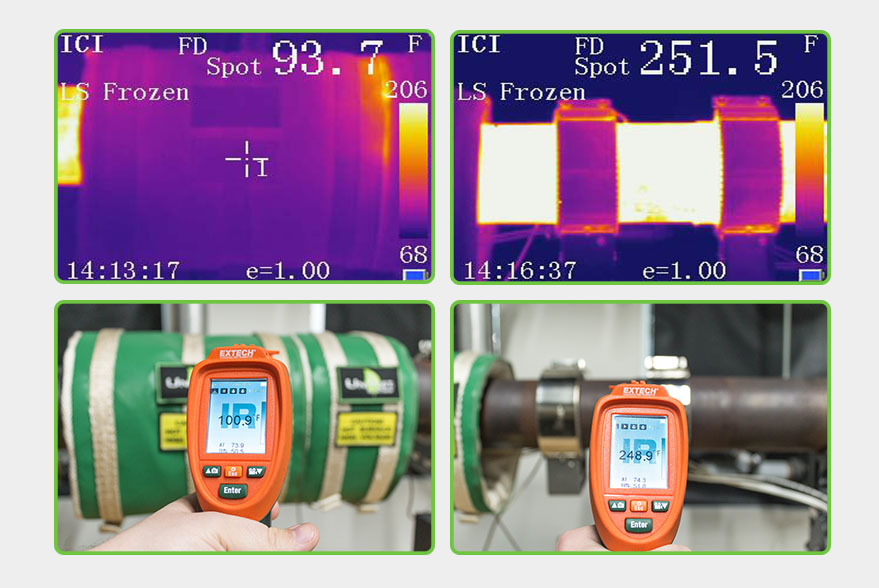

- UniVest® Insulation Jackets create a SAFER WORKING ENVIRONMENT for your employees and increase equipment lifespan by protecting key components from high temperatures.

- UniVest® Insulation Jackets are made with STANDARD, READILY AVAILABLE, OFF-THE-SHELF COMPONENTS that can be easily configured for any custom configuration requirement.

- UniVest® Insulation Jackets are COMPLIANT WITH OSHA SAFE-TOUCH STANDARDS for exposed heated surfaces (if there is a potential for injury).

- UniVest® Insulation Jackets deliver an INCREASED CONTROL OF PROCESS TEMPERATURES to enhance production capacity by reducing the amount of energy needed to keep equipment running at high temperatures.

_____________________________________________________________________________________________________________

INDUSTRIES & APPLICATIONS:

Using UniVest® Insulation Systems IN …

- Plastic processing

- Gas pipeline compressor stations

- Oil and gas extraction

- Petroleum and coal products manufacturing

- Cement plants

- Chemical plants

- Ethanol plants

- Pulp and paper mills

- Steel and metal manufacturing and refineries

- Glass manufacturing and melting

- Incinerators

- Brick manufacturing

- Artificial synthetic fibers, rubber, and resin manufacturing

Using UniVest® Insulation Systems ON …

- Process heaters

- Furnaces, ovens, or kilns

- Conductive, convective, and radiative losses from hot equipment surfaces

- Conductive, convective, and radiative losses from heated product streams

- Natural gas pipeline compressor

- Other natural gas-fired turbines or oil-fired turbines

- Reciprocating engine exhaust

- Furnaces, air compressors, and internal combustion engines

UniVest®: How to Measure

UniVest®: How to Install

UniVest® Blow Torch Test

|